WATER COOLED SCREW CHILLER

- Residential air condition

- VRV air condition

- FAN COIL UNIT

- Refrigeration System

- Air handling units

- Air cooled chillers

- scroll chillers

- Air to water heat

- Package units

- hygienic air handling units

- Data center package unit

Capacity:

190~1300kw

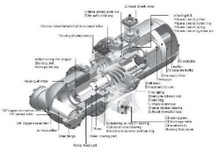

COMPRESSOR:

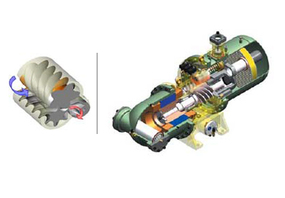

High efficiency twin screw compressor

1. Adopt international famous brand twin-screw compressor, 5:6 unsymmetrical structure, specially made slide valve structure, can save 10% energy comparing with common screw compressor;

2. Star-Delta start method, reduce the start current;

Capacity control is infinitely variable between 25% and 100% enabling capacity requirements to be closely matched by modulating the sliding valve position according to the chilled water control condition.

This semi-hermetic twin-screw compressor is developed especially for applications in air-conditioning and

refrigeration. With a built-in high operating load design, each compressor is high efficiency and reliability in

all working conditions such as thermal storage, and heat pump system. Each compressor has the latest and

advanced 5 to 6 Patented Profile design

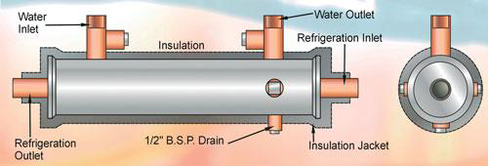

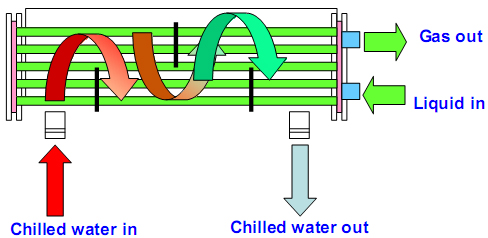

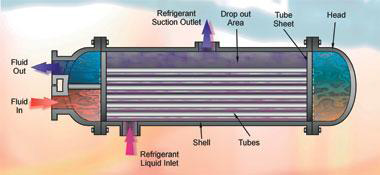

EVAPRATOR,

DRY TYPE:

A typical arrangement of a dry type or direct

expansion shell and tube chiller is shown in

Fig 1. It is a more common arrangement for

the refrigerant inlet and outlet to be at the

same end as shown in the cutaway illustration

in Fig. These are normally used with positive

displacement compressors such as reciprocating

, rotary or screw machines.

FLOODED TYPE:

There is also a type of shell and tube chiller where the water runs through the tubes and the refrigerant flows over the outside of the tubes within a closed shell. This is known as a hooded arrangement or flooded type. However, this arrangement is not as common as the dry type of construction. Approximately 50% to 75% of the tubes are immersed in liquid refrigerant and the space above provides an allowance for the vapor generated through evaporation of the liquid below. This type is more often used with screw or centrifugal type compressors.

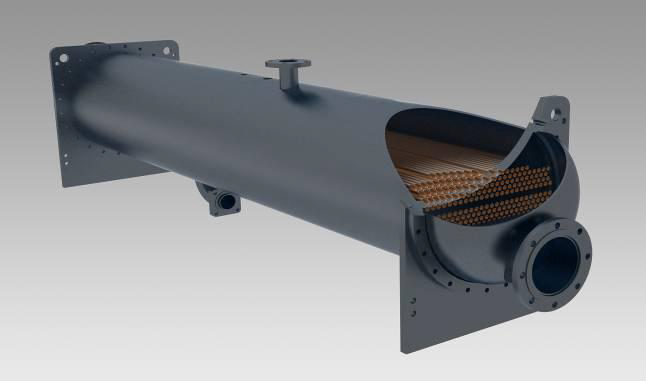

Condenser:

Shell and tube heat exchanger with external still sheet shell and internal cooper pipe bundled. The cooper pipe are expanded in to terminal plates at the end. The head plates can be removed for maintenance procedures. The water connection can be used for operation with cooling tower.

It can be designed to suitable for different fouling factors. There is a reserved 15% heat exchange capacity design which can make the condenser provide enough capacity even the cooling water temperature reaches 32℃ or there is fouling inside the water system.

Electronic control:

The units output part have special connection wire ,can realize inter-lock control with the cooled water pump ,every controller have R485 communication interface and software convenient for the customer.

- easy to program flexible control to user

- Temperature control with ±0,5°C tolerance

- powerful control function, user can use PID method to control the operation, adjust the Operation status according to heat load to realize optimized operation。

- Current limiting and demand function

- Lead-Lag control of compressors

- System protection functions, unit can stop to enter protection when malfunction Happens, display the malfunction code and alarm to the operator;

- Dual set point option

- Alarm & predictive maintenance history

- Minimum heat load start, the unit can check the last time operation condition and supply Minimum start method, reduce the impact to the electricity network and improve the system stability;

- PLC can check and supply different solutions to different system