TOYO-ac VRV SYSTEM

- Residential air condition

- FAN COIL UNIT

- Refrigeration System

- Air handling units

- Air cooled chillers

- Water cooled chillers

- scroll chillers

- Air to water heat

- Package units

- hygienic air handling units

- Data center package unit

VARIABLE REFRIGERANT

available in cooling only, heat pump and heat recovery formats. • a rapid response system in which up to 64 indoor units can operate on the same refrigerant circuit. • an inverter driven compressor enables the output of the outdoor unit to be modulated in accordance with the cooling/heating demand of the zone which it controls.

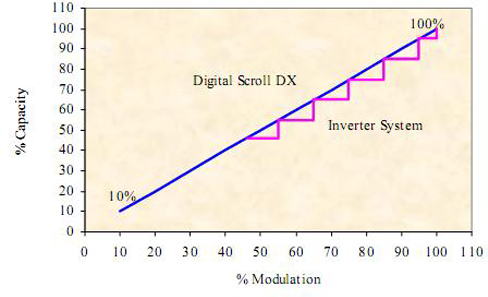

Digital Scroll Compressor operation

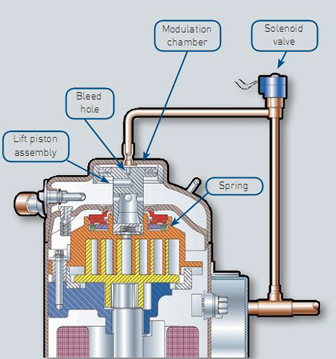

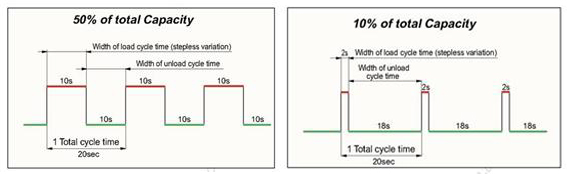

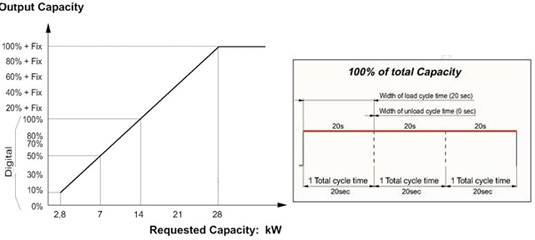

The Digital Scroll Compressor uses a simple and effective method to modulate the capacity of an AC, giving unparalleled performance in the modulation feld.To modulate the capacity the Digital Scroll operates in two stages, the “loaded state” in which the compressor works as a normal Scroll compressor at full capacity and mass fow, and the “unloaded state”, where there is not capacity and mass fow. During the “unloaded state” there is a separation between the scrolls. Once th scrolls separate, any gas passing through is no longer compressed. Changing the cycle time (“Loaded state” time and “Unloaded state” time) determines the capacity modulation of the compressor.

The biasing chamber communicates with the by-pass circuit. When the compressor is in the loading state, the pressure inside the biasing chamber is equal to the compressor’s discharge pressure, as the PWM solenoid valve keeps separate the two segment of the by-pass circuit between the biasing chamber and the suction pipe (see figure). In this situation the “loading”geometrical configuration is possible as the stator is pressed down by the compression’s pressure itself.

Depending on thermal load conditions,for cooling or heating operations, the PWM solenoid valve (2-ways), opens theby-pass circuit, thus allowing the communication between the discharge and suction sections. In this way the respective pressures become equal and coincident to the suction pressure. The pressure in the compression chamber no more self-balanced, (self-balancing due to the presence ofthebiasingchamber), pushes the stator upward,producing a circumferential port, thus opening the compression chamber . So the previously described “unloading”configuration, is achieved.

FAN

axial type aluminum (80/100) or ABS plastic(othermodels) fans with direct drive motor. All fans are statically and dynamically balanced for quiet operation.

Intelligent technology

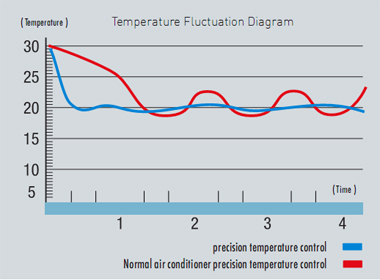

Comfortable and pleasant intelligent temperature control. The advanced temperature control system maintains the indoor ambient temperature at a precision of ± 0.5º C. This precise temperature control improves the feeling of comfort. The different indoor units have.

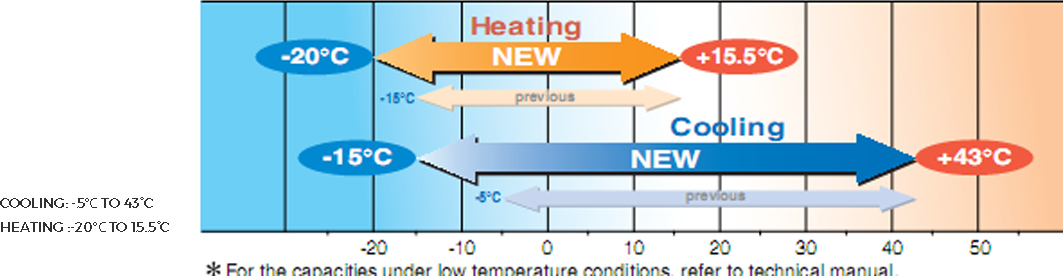

Range of Operation

TOYO digital scroll DX is more energy saving than inverter VRF

1. General Power Loss

- Under unload status, the energy consumption of TOYO digital scroll DX system is about 10% of the rated one, and there’s no power loss under loaded status, thus the total power loss of York digital scrol

2. Part Load Condition

- Capacity modulation range of TOYO digital scroll dx system is 10%-100%. For a typical 5HP system the lowest capacity is 5HP*10%=0.5HP. Even when there’s only one small indoor unit (1HP) is running, the whole system can operate properly without any bypass.

- Normal inverter compressor’s capacity modulation range is 33%-107%. For a typical 5HP system, the lowest capacity is 5HP*33%=1.65HP. When there’s only one small indoor unit (1HP) is running, system bypass is required which will reduce the efficiency.

3.High Ambient/ High Load Operation

- Since the compressor speed is constant, TOYO-AC digital scroll DX system can operate properly under high ambient/ high load conditions.

- For inverter VRF system, the discharge temperature will rise rapidly under high speed operation, and liquid refrigerant cooling is necessary to protect the compressor and reduce the efficiency at the same

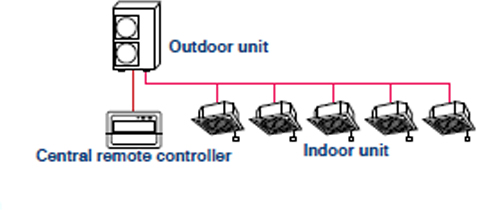

Advanced Control System

64 groups (zones) of indoor units can be controlled individually same as LCD Remote control

- Max. 64 groups (128 indoor units controllable)

- Max. 128 groups (128 indoor units) are controllable by using 2 central remote controllers, which can control from 2 different places.

- Zone control

- Malfunction code display

- Max. wiring length 1,000 m (Total: 2,000 m)

- Combination with Unified ON/OFF controller, schedule timer and BMS system

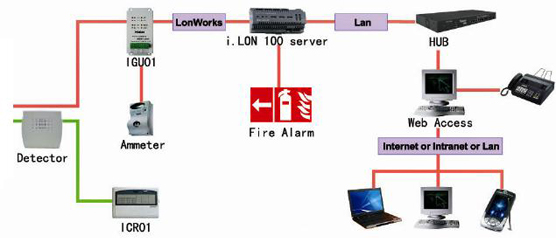

intelligent built-in management system

1-Low cost:

- Simple equipment and high performance will greatly reduce the air Conditioner operating cost

2- Easy operation:

- the software adopts personalized graphic interface,, only mouse action will finish the operation,, convenient for the manager.

3- Universal protocol :

- the control system adopt Lon works protocol, , easy to connect with other BMS system

4- Powerful management function:

- the system can realize system monitor,, routine management,, simultaneous control with fire alarm signal,, multiline alarm mode ,and malfunction analyze, ante accounting,, cooling &heating condition inspection etc..

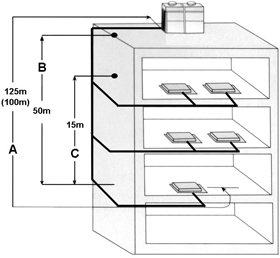

PIPING LENGTH

A - Maximum equivalent piping length from the outdoor unit to the farthest indoor unit.

B - Maximum height difference between the outdoor unit and the lower (or higher) indoor unit.

C - Maximum height difference among indoor units.