PACKAGE UNITS

- Residential air condition

- VRV air condition

- FAN COIL UNIT

- Refrigeration System

- Air handling units

- Air cooled chillers

- Water cooled chillers

- scroll chillers

- Air to water heat

- hygienic air handling units

- Data center package unit

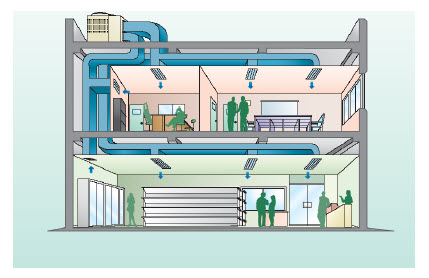

TOYO-AC Rooftop Units Applications

Rooftop packaged systems are unobtrusive, quiet, and designed to provide year round comfort – warming in winter

and cooling in summer. TOYO-AC's wide product range offers a unit of performance capacity to suit small to large packaged air conditioner applications, e.g. offices, shops, motels, fast food outlets, restaurants, petrol stations, open plan office and work spaces, supermarkets, shopping malls and auditoriums.

Units are suited to high static pressure applications where large volume spaces are to be air conditioned. Long pipe and duct runs are possible enabling greater installation flexibility. This range of units has been developed to meet the needs of typical applications. Should you have special requirements, such as higher air flows or greater sensible duty units contact your nearest TOYO-AC representative.

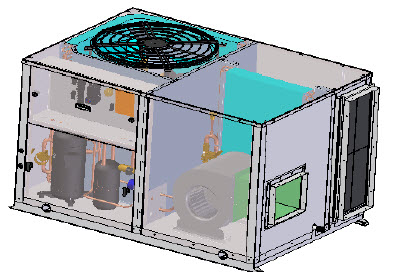

Components or Assembly Descriptions

A) Quiet operation

The packaged Rooftop series are basic constructed and engineered with noise reduction as a first consideration, low noise mounted fans are used, 15mm wave type acoustic Insulation for compressor section and compressors are mounted on vibration isolators.

B) Low Cost Installation

Units are factory assembled and pre-charged, with a single point electrical connection. On arrival to the job site they are ready to be lifted to their operating position through the lifting supports available on the units. Heavy grade steel casing with polyester epoxy powder electrostatic oven-baked paint of coating finish, designed for outdoor installation with 10mm insulation for evaporatorsection only. All units are provided with an 8mm thickness aluminum frame filter that slides out or easy cleaning or replacement.

E) Compressor

The compressor used is hermetic refrigerant gas cooled, with internal thermal protection in each phase, scroll type. The terminal boxes are rain tight, starting is direct-on-line. With high efficiency, low sound, so as to match all other Bright products’ reliability and efficiency.

F) Evaporator and Condenser Coils

The evaporator and condenser coils are designed to deliver their respective duties at optimum performance at all design conditions. Coils are manufactured from seamless copper tubes mechanically expanded into aluminum fins. All coils are tested at 30kg/cm (450 Psi) air pressure, under water to avoid leakage. They also undergo dry chemical cleaning after manufacturing for optimum system cleanness.

H) Condenser Fan Motor

All fans motors are of totally enclosed air-cooled, internal thermal current overload protected, with class “IP56”

electrical insulation.

J) Evaporator Fan Motors

Motors are of the totally enclosed induction type, with fan motor assembly placed on a floating base with a flexible connection at the fan/casing interface. All fan motors of direct-driven are of the 3-speed type, highly efficient induction type motors, totally enclosed air-cooled, squirrel-cage type, internal thermal current protected and with class “B” insulation. Fan motors with V-belt-driven type are of 1 speed type.

K) Filters

All Models are provided with 8mm thickness aluminum frame filter (as standard features). Other filters are available upon request.

M) Insulation

All units are internally lined with 10mm thermal insulation for coil and fan section (evaporator side only).

N) Easy Installation

The package rooftop has a compact design. It is supplied as a complete package ready for operation, with no extra controls or other items to be installed. The units have a single powepoint entry with simple connections. All units are designed to ensure maximum compliance with international standards. Quick start-up is assured once installation is completed, as each rooftop unit is manufactured in an ISO9001:2000 listed facility to guarantee quality. All units are tested at the factory to provide reliable start up.